|

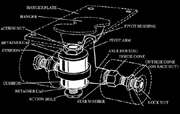

D) Replace worn

action cushions, pivot bushings, axle nuts, axle washers

and kingpins as needed, this will extend the life of your

trucks and make them perform properly. E) Use harder cushions for tighter trucks and softer cushions for looser trucks... mess around until it feels right. 3) Wheel Maintenance: A) Smaller harder wheels are generally preferred for more technical skating (lighter and lower center of gravity), while larger softer wheels work best for commuting, cruising and goin fast (smoother and more top end speed). It will take some experimentation to figure out exactly what's right for you. B) Front wheels usually wear from the outside in and read wheels from the inside out, by rotating your wheels corner to corner you will extend the life of your wheels. C) Don't let garbage trucks run over your board and do a half block skid on it as this may result in flat spots. D) Don't purchase and attempt to use square wheels. E) Wider wheels make stable landing platforms, narrower wheels are more nimble. 4) Bearing Maintenance: A) Stay away from semi precision bearings, choose something that is full precision. B) Stay away from packaged, promoted, hyped up bearings, most of these bearings are all highly overrated. C) Use washers on the inside of your axles to prevent the bearings shields from becoming worn out. D) Clean the crap off the outside of your bearings with an old rag once in a while, this will prevent crap being pulled inside your bearing and killing it. E) Don't use a screwdriver to remove your bearings, it can damage the seals. Use the truck axle to pry em out, it's the perfect size. F) Don't use a socket wrench to push bearings in or you will damage the seals, instead put the bearings on the truck axle, then push the wheel onto the bearing. 5) Riser Pads: A) If you are running bigger wheels, you may have to consider riser pads. If you can get away without using them and deal with the occasional wheel bite that's good, you will keep your G's low. If a riser becomes necessary (usually around a 60mm wheel) use the smallest one you can ... the more rise you have, the more tippy your ride will feel. THAT'S IT FOR NOW. USE COMMON

SENSE AND REMEMBER, WHEN YOU'RE EATING DINNER DON'T STAB

YOURSELF IN THE EYE WITH A FORK CAUSE IT MIGHT HURT. |